Solid Copper Hollow Point -vs- Jacketed Hollow Point

Posted by Defiant Contributor~ J.B. on Apr 2nd 2023

Which is better, a solid copper bullet or a standard jacketed hollow point? To answer this question, we must first explain the differences between the two. Let's set the foundation with a brief history of ammunition.

Since the invention of gunpowder and its subsequent use in firearms, lead has been the primary material utilized for projectiles. Due to its properties, lead was cheap, easy to manufacture, and versatile. Lead could be easily melted down over a fire and poured into molds of all sizes for various types of firearms. It wasn't until 1882, with the invention of copper jacketing, that the modern bullet was born. The copper, due to its heat resistance, allowed for higher pressures. This new jacketing allowed for many changes to bullets and firearms alike.

So, what exactly is a jacketed hollow point? Think of a copper jacket on a bullet as similar to a jacket you would wear. The copper acts as a covering or wrapping for the lead inside. A hollow point is exactly what it sounds like. The tip of the projectile is concave or hollow, allowing for the bullet's expansion on impact. Your standard jacketed bullet is either bonded or non-bonded. With non-bonded, the lead simply rests inside the copper jacket, and with bonded, the lead is fused to the copper jacketing.

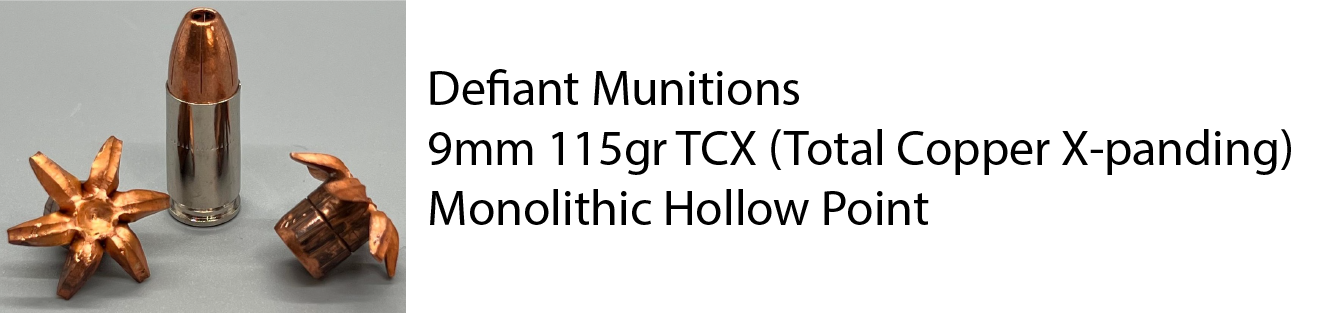

A monolithic or solid copper projectile like the TCX line from Defiant Munitions is the next evolution in bullet technology. With a solid copper bullet, the centuries-old method of using lead projectiles is done away with. Because there is no soft lead core to come apart or deform on impact, the TCX (Total Copper X-panding) bullets offer greater consistency in penetration and expansion when compared to jacketed hollow points. The increase in penetration is particularly in the presence of obstructions. This is known as being "barrier blind." Being barrier blind means the bullet does not expand or deform when it contacts certain barriers, such as glass, drywall, or thin metal like car doors. Then there is the reliability of the expansion. Testing of traditional hollow points has shown, in some cases, an up to 30% failure rate in the expansion of standard hollow points. The tip of the projectile often becomes clogged with clothing or animal hide and cannot expand properly. These advantages of a solid copper bullet, like the TCX ammunition, translate to better results down range.

There is also another, often less discussed, benefit of solid copper projectiles for conservation. As most people are aware, lead can be toxic if ingested. For this reason, we no longer use lead in paint or plumbing in our homes. In recent years studies have been conducted looking into heavy metal toxicity in many species. Most of these species are scavengers, such as raptors and coyotes. Particular work with the California Condor has shown a significant correlation between their declining numbers and lead poisoning. The theory is that these scavenging animals are ingesting lead bullets from the gut piles of game animals. Findings from studies like these have caused many jurisdictions to outlaw the use of lead bullets in hunting. Some have even suggested that the meat from game animals harvested with lead bullets could contain harmful amounts of lead.

Whether defending your life or putting food on the table, solid copper projectiles like the TCX line offer many distinct advantages. With greater penetration and more consistent expansion, you can have confidence that you'll get the job done down range and be able to sleep well, knowing that you're not introducing toxic heavy metals into the ecosystem.